158 GWh – Annual Generation of SUPCON Delingha 50MW Tower CSP Project Released

2022.08.16 From: Cosin Solar

The operational data of SUPCON Delingha 50MW Tower CSP Project arrived as expected. From August 6, 2021 (after the completion of the turbine rectification) to August 5, 2022, the cumulative actual power generation of the plant for the complete year was 158 GWh, reaching 108% of the annual design power generation (146 GWh) and setting the highest operational record of the same type of power plant in the world.

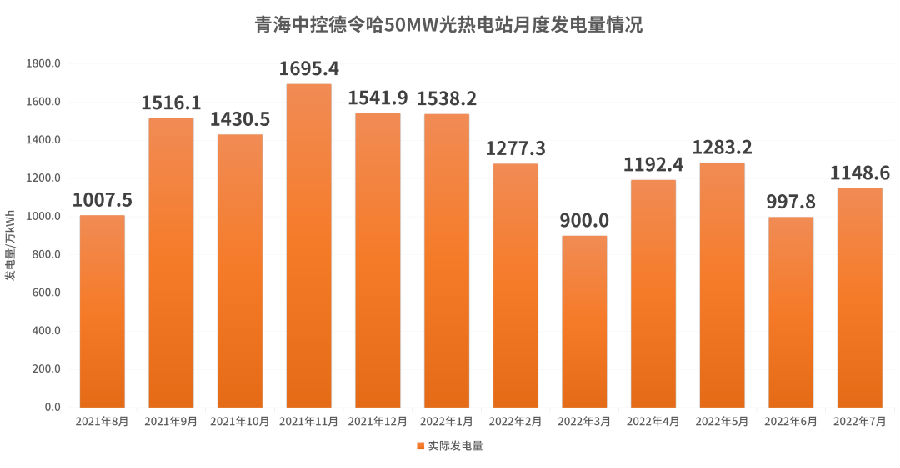

Figure 1: Power plant power generation data for the last 12 months (including: no power generation from August 1 to 5, 2021 due to rectification, and cumulative power generation from August 1 to 5, 2022 is 2,782,400 kWh)

Although the weather at the site of the power plant was not good in the past month, experiencing continuous rainy days and sandstorms, but still achieved the excellent operation performance of 158 GWh of cumulative power generation in a full year. It became the first tower-type molten salt storage solar thermal power plant in the world whose annual actual power generation exceeded the annual design power generation.

The system of solar thermal power plant is complex, and the factors affecting its production include system design, system performance, equipment reliability, operation optimization, etc. It is easy for the power plant to generate electricity but not simple to achieve production target.

Here are the reasons for the success of Qinghai Supcon Delingha 50MW solar thermal power plant

1 Optimal matching of each system to improve the overall operating efficiency of the system

The match between the heat collecting system, the heat storage and exchange system and the power generation system is a prerequisite to determine the performance of a solar thermal power plant. The design of solar thermal power plant requires comprehensive consideration of several factors to improve the efficiency of each system and reduce investment costs. The power plant design software independently developed by Cosin Solar can realize the optimal matching of each system through big data calculation and repeated iterations according to different boundary conditions.

2 High-efficiency heat collecting system to ensure heat collection and power generation

The performance (efficiency) of the heat collecting system is the basis for determining the performance of a solar thermal power plant. And the concentration accuracy directly determines the efficiency of the heat collecting system, which in turn affects the efficiency and power generation of the solar thermal power plant.

Cosin Solar has greatly improved the efficiency of the heat collecting system by applying its self-developed high-precision intelligent heliostat, high-efficiency correction system, solar field control system, etc, and optimizing the solar field arrangement method and the structural process design of the receiver.

01 Optimized solar field design method

The special solar field design software of Cosin Solar is the basis for high efficiency of the solar field.

-Optimization principle: solar field from the viewpoint of the receiver - no shading

-Solar field efficiency is about 1.5% higher than conventional radiation arrangement

-Approximately 2.5% improvement in land utilization over conventional radiation arrangement

02 High-precision intelligent heliostat

The high-precision intelligent heliostat developed by Cosin Solar is equipped with high surface and tracking accuracy, which can accurately reflect sunlight to the designated position of the receiver, improve the quality of the light spot, reduce the energy overflow on the receiver, effectively improve the photoelectric conversion efficiency, and thus increase the power generation capacity of the solar thermal power plant.

03 Highly efficient and fully automatic calibration technology

Regular calibration of the solar field is very important to ensure the concentrating accuracy. The automatic calibration solution based on machine vision adopted by Cosin Solar has 25 times higher calibration efficiency than the traditional whiteboard calibration solution, and can realize automatic cyclic calibration without staff involvement.

•During the construction period, due to the deviation of the installation of the heliostat, it is necessary to calibrate the whole field heliostat once before commissioning. By adopting the calibration system of Cosin Solar, the calibration time of the Solar field can be greatly reduced, thus shortening the project commissioning period; at the same time, since the installation process of the heliostat does not require precise positioning and measurement of deviation, the installation cost can also be greatly reduced.

•After the power station is put into operation, the accuracy of the heliostat will change due to the change of settlement of the heliostat foundation and the influence of external environment such as wind speed and temperature. The calibration system of Cosin Solar can perform high-frequency periodic calibration of the operating solar field to ensure that the whole field heliostats are always at the best accuracy level throughout their life cycle.

04 Highly integrated control technology

Based on nearly 30 years of experience in the field of control system, Cosin Solar has independently developed the solar field control system, which can realize the cluster control of large amount of heliostats, ensuring the safe and stable operation of the power plant heat collecting system, while greatly improving the utilization rate of solar resources, and thus enhancing the power generation of the power plant.

-Control system software and hardware are developed completely independently. Solar field control system, receiver control system, plant DCS, etc. are deeply coupled and control interlocked, realizing fully automatic control of the main operation process.

-Transplantation of the mature concept of DCS control system, maintain multiple redundancy for control system server, power supply and network.

-Reliable control system to ensure accurate tracking in the solar field and reduce light spot overflow, while ensuring uniform energy on the surface of the receiver.

05 High efficiency and high safety receiver

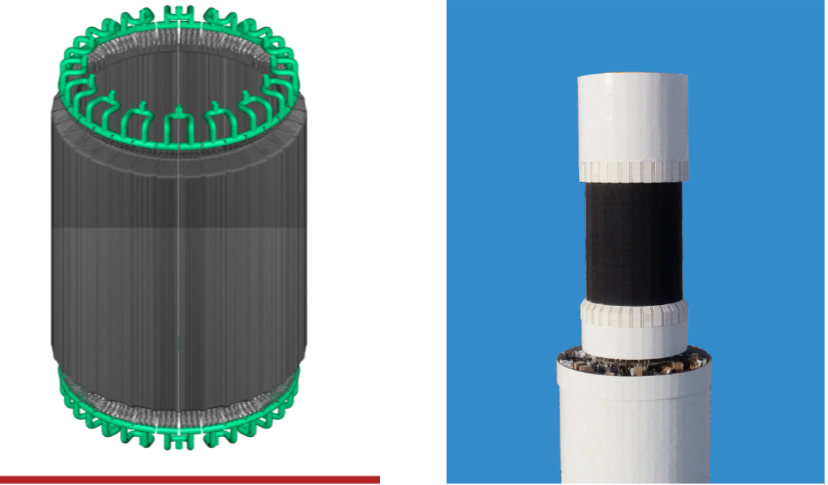

The molten salt receiver, which uses molten salt as the working medium, is exposed to severe working conditions such as high temperature, frequent and violent changes in high and low temperature, and corrosive environment. For this reason, Cosin Solar has optimized the design from several aspects to ensure the safe and efficient operation of the molten salt receiver.

-Material selection: high nickel alloy tubes, resistant to high temperature, corrosion, thermal stress and thermal fatigue; high absorbance coating to improve the absorption rate of light resources.

-Structure design: flexible structure, resistant to thermal stress and thermal fatigue; modular factory prefabricated, avoiding on-site processing, ensuring the performance of the receiver and improving installation efficiency.

-Control system: solar field control to ensure uniform temperature on the surface of the receiver, deep coupling between the receiver control system and the solar field control system, chain control to reduce thermal shock.

-Anti-freeze plugging: optimize the internal pipe structure to reduce the occurrence of freeze plugging working condition; real-time monitoring of receiver surface energy, monitor the surface temperature change at any time to find freeze plugging in time; automatic salt control system, use the solar field energy to melt salt and unblock under freeze plugging working condition.

06 Comprehensive advantages of Cosin Solar heat collecting system

1.high-precision intelligent heliostat + high-efficiency automatic correction system + highly integrated solar field control system to ensure the concentrating accuracy of the whole solar field in the whole life cycle.

2.high precision concentrating and high efficiency receiver bring high efficiency of the whole concentrating heat collection system.

3.high efficiency concentrating and heat collection system provides guarantee for heat collection and power generation of the power plant.

Cosin Solar's capability and level in concentrating collector system has been widely recognized by the industry, leading the preparation of IEC international standard "Solar field Control System for Solar Thermal Power Station", as well as two national standards "Technical Requirements for Tower Solar Thermal Power Station Heat Collecting System" and "Technical Requirements for Tower Solar Thermal Power Station Heliostat".

3 Reliable molten salt storage and heat exchange system, ensuring high quality power generation in power plants

Cosin Solar has deeply studied the characteristics of molten salt system and developed its own process optimization technology for molten salt storage and heat exchange system, which has greatly improved the reliability and availability of special equipment.

-Adopting a unique structural design for molten salt storage tanks, which can reduce heat loss while increasing the load capacity; adopting an even-flow design for the tank interior, which significantly improves the reliability of the tank.

-The molten salt heat exchanger adopts the world's first double-row design scheme, and makes a lot of optimization design for the heat exchanger structure, which greatly improves the availability of the equipment; it can also realize a wide range and rapid load change, which achieves better load regulation depth and speed than traditional thermal power.

-The joint design of molten salt pump and piping and platform, overcome technical problems such as the design of wear resistance of molten salt pump under high temperature environment and the design of molten salt valve seal.

4 Reliable and controllable key equipment to ensure stable operation of the power plant

The reliability of key equipment is an important factor affecting the operational performance of solar thermal power plants.

01 Key equipment design and processes, online inspection, to avoid the flow of unqualified products. manufacturing of heat collecting system is controlled independently throughout the process

-Key equipment such as reflecting mirrors, welding parts, sheet metal parts and electric control components all adopt automatic production devices, configured with special tooling to ensure the consistency of quality in the manufacturing process.

-Automatic mirror assembly line, PLC human-machine interaction control, automatic loading, automatic positioning, automatic flow between

02 Equipment integration and optimization of molten salt storage and heat exchange system

Cosin Solar cooperates closely with various equipment manufacturers and participates deeply in the equipment design and manufacturing installation process, mastering the key performance and control points of the equipment, forming a complete quality control process for the equipment of molten salt storage heat exchange system, and ensuring the operational reliability of the key equipment.

03 The reliability of key equipment has been proven

-The most application performance in China: three tower CSP projects with the longest application of nearly 10 years.

-Harsh application environment test: high altitude (above 3000m), cold weather (minimum

-37℃), and strong sand and wind.

5 Fully automated operation system for optimal operation strategy

The key of solar thermal power plant operation optimization is to maximize the utilization of solar resources under the premise of safe and stable operation of the receiver.

Key Issues

Clouds are an important factor affecting power plant heat collection and power generation, for example, Delingha site has more than 200 cloudy days a year. How to choose the operation strategy in case of incoming clouds?

•Continued operation: May result in uneven surface temperatures on the receiver, affecting safe operation.

•Shutdown of the field for salt evacuation: The easy option for the operator, but it causes waste of solar resources and requires warm-up of the receiver and piping for restarting after the cloud.

Solutions

•Cloud prediction system: through cloud identification and cloud motion tracking, DNI prediction function within 30 minutes is realized to help operators choose the best operation strategy.

•Solar field energy scheduling system: Through the unified scheduling of the energy of the whole solar field, it realizes the uniform distribution of energy on the surface of the receiver in the case of incoming clouds, without huge changes in surface temperature, and avoids shutting down the field and salt evacuation as much as possible, thus realizing the maximum utilization of solar resources.

Automatic operation system of heat collecting system

In order to improve the stability and safety of system operation, the automatic operation software of heat collecting system independently developed by Cosin Solar realizes the fully automatic control and one-key start/stop of the main operation process of heat collecting system, which reduces the system efficiency decline and equipment operation risk caused by human factors.

-Meteorological system, cloud monitoring system, infrared system and solar field control system deep coupling, to achieve automatic operation strategy for complex working conditions such as incoming clouds.

-Automation of abnormal working conditions: automatic detection and treatment of blocked tubes of receivers, over-temperature safety protection, power failure safety chain, etc.

Cloud Prediction System

The first cloud prediction system in China, with cloud identification and motion tracking functions, realizes DNI prediction function within 30 minutes.

Simulation platform for heat collecting system

•Operation simulation.

-Simulation of key equipment such as receiver and solar field, supporting the simulation of temperature distribution data on the receiver.

-Simulation of the whole process of system preheating, heating up, operation and shutdown.

-Operation data output function.

•Training operation.

-Consistency with the software platform actually running at the project site to enhance operational training effect.

-Interactive cooperation between the teacher portal and the trainee portal to realize the online assessment function.

•Fault simulation.

-Operation simulation and chain protection after a fault occurs.

-Help operators to develop fault handling plans and shorten fault handling time.

Automatic cleaning vehicle for heliostat

It is very important for solar thermal power plants to maintain the cleanliness of heliostat mirrors. Cosin Solar's innovative fully automatic driverless cleaning vehicle with automatic navigation and water/dry cleaning functions can significantly improve solar field cleaning efficiency, ensure mirror cleanliness, and reduce operating costs.

Summary

In comparison with the uneven operational performance of similar solar thermal power plants at home and abroad, we should realize that solar thermal power plants are "easy to build, but not easy to reach production". For a solar thermal power plant with huge investment, whether the designed power generation capacity can be achieved on schedule is a prerequisite to determine whether the project owner can achieve the expected revenue. Therefore, when selecting the key technology and core equipment for a solar thermal power plant, the past performance should be the primary factor for the owner to consider.

Behind the excellent operation performance of SUPCON Delingha 50MW Tower CSP Project is Cosin Solar's many years of dedicated research and development and engineering practice in the field of tower solar thermal power generation, and our long-term investment and accumulation in design optimization, system performance, equipment reliability, operation strategy, etc., which fully proves the advancement, maturity and reliability of our self-developed tower solar thermal power generation technology.

Under the current situation that "Solar Wind and Storage" grand projects are vigorously promoted, Cosin Solar will rely on the valuable experience gained in the construction and operation of SUPCON Delingha 50MW Tower CSP Project to serve the project owners and create value for them with advanced technical solutions, mature and reliable core products and perfect operation support services.

SUPCON Delingha 50MW Tower CSP Project

One of the first national solar thermal power demonstration projects, has an installed capacity of 50MW, with 7-hour molten salt energy storage system, solar field aperture area of 542,700 square meters, design annual power generation capacity of 146 GWh. With an annual saving of 46,000 tons of standard coal, and an emission reduction of about 121,000 tons of carbon dioxide gas, it has good economic and social benefits. The power station adopts the core technology of tower-type molten salt CSP developed by Cosin Solar. The operational performance of the power station has passed the complete technical evaluation by Fichtner, a German independent engineering consulting company, which has determined that its technology has reached the most advanced level of similar power stations in the world.

More from CSP Focus

NextChina pilot CSP plant progress—SunCan Dunhuang 100MW tower project to operate by Aug. 2018

SolarReserve Appoints Tom Georgis as Chief Executive Officer

World’s largest concentrated solar power project starts commercial ops in Abu Dhabi

Global solar thermal power revolution urges for CSP innovations

Chile to build a 1,007MW CSP-PV integrated solar power project

Leave your thoughts here

Reports(Member Only)

See more+-

CSP Focus Membership Proposals

We are now proposing CSP Focus Membership, hoping to better serve our members to keep pace with the latest updates of ongoing CSP projects worldwide, and to establish and maintain business relations with major shareholders of the projects. CSP Focus offers to Membership exclusive access to:1. Daily/Weekly update and analysis on CSP policies, projects, technologies, market trend and corporate relea

-

The Latest CSP Focus Monthly Update

Join CSP Focus Membership to Get the Latest CSP Focus Monthly Update December Edition.

-

CSP Project Monthly Update 2022 December Edition

CSP Focus is presenting CSP Project (China) Update 2022 December Edition.Detail report is available for CSP Focus Membership.

-

Presentations-CSP Focus China 2021

The Report is for CSP Focus Members only.

Upcoming Events

See more+-

12th CSP Focus China 2022

2022.04.21-22 Beijing

-

11th CSP Focus China 2021

2021.10.28-29 Beijing

-

10th CSP Focus China 2020

2020.10.22-23 Beijing, China

Project Updates

See more+-

Lanzhou Dacheng Dunhuang CSP Project

Asia Pacific-China,Operational,Parabolic Trough

-

Luneng Haixi 50MW Molten Salt Tower CSP Project

Asia Pacific-China,Operational,Power Tower

-

Dubai 950MW NOOR Energy 1 CSP+PV Project

MENA-UAE,Under construction,Power Tower

-

Power China Gonghe 50MW Molten Salt Tower CSP Project

Asia Pacific-China,Operational,Power Tower